- Conventional and Pre-Engineered Building Solutions

- Hydroelectric, Oil & Gas, and Mine Projects

- Heavy Industrial, Warehouses and Commercial Buildings

- Aircraft Hangars, Hotels & Resorts, Arenas and Community Centres

- Pulp & Paper Projects

Our long safety history allows us to operate on the strictest build sites, including the Oil Sands – a privilege earned by only a select few. We apply the same safety philosophy to any project.

Efficiency is the result of knowing what to do, when to do it, and how to best approach the task at hand. Our team of people have extensive backgrounds in steel building design, detailing, and manufacturing and we can help you plan your project at the early stages to be more successful. We apply our knowledge to be part of the solution and can help solve problems in the field. We work alongside other trades so that everything comes together in an efficient, safe, and timely manner.

- Standing Seam Roofs

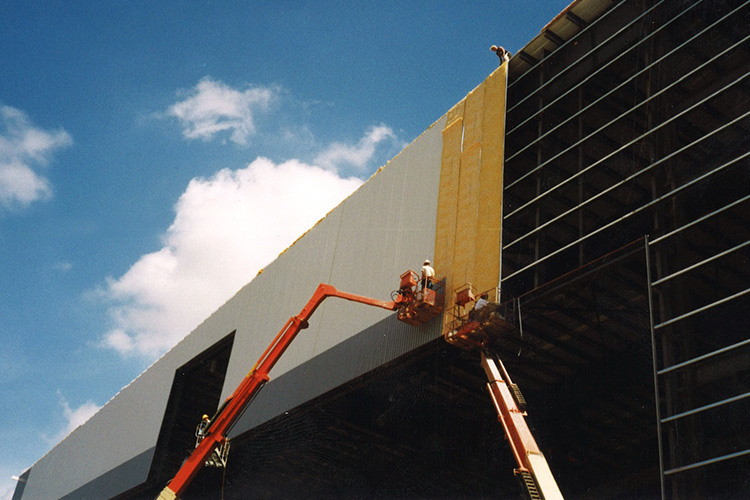

- Insulated Wall Panels

- Exterior Cold-Formed Steel Panels

- Hidden Fastener or through-fastened

- Interior Steel Liner

- Single Skin or Built-Up Systems

Our years of experience installing steel cladding allow us to know the pitfalls of taking shortcuts in ironworking – and we won’t do it.

The finished look of a steel building has everything to do with the experience, attention to detail, diligence, and care taken during the installation to do it right. Even the smallest blemish on a flat surface can have a huge impact and become a real eyesore. Proper application of sealants, insulation, weather-stripping, and fasteners affects the performance of the building by preventing leaks, improving the performance of HVAC systems, and avoiding condensation. Having the structural steel erected square and plumb is required before beginning the cladding. You don’t want to have a poorly installed substructure affect the look or performance of the finished product.

- Conventional or Pre-Engineered Steel Building Designs

- Supply and Erect Combinations

- Steel Cladding or Structural Components

- Heavy Haul with Structural Steel Module Placement

Including the erector early in the process will also help to make sure you have one when you need it! Scheduling the erector can be difficult to do at the last minute.

There is nothing better for the success of your project than a coordinated group of companies who can work efficiently together and save you money. In our long business history, we’ve built relationships with companies who bring a similar level of professionalism and quality to the job site. We’re happy to coordinate our teams, and work with the designers during the early stages of your project to help reduce work in the field—which saves you time and money.

- Structural Building Modules

- Pipe Rack Modules

- Pipe Bridges

- Rooftop Equipment

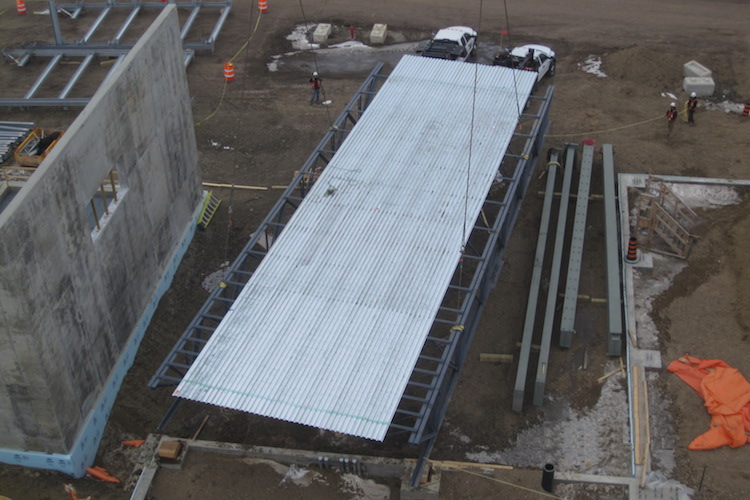

- Engineered Roof Bay Lifts

Including the erector early in the process will make sure that schedules line up, to help prevent setbacks during the construction process.

When erecting steel buildings, PR Construction Ltd. will pre-assemble entire bays of roof and wall sections on the ground and then lift them into place. This minimizes the work that is required at heights and increases worker safety. In order for this to happen properly, each bay lift is planned in advance and engineered to ensure that the structure can be lifted safely. The same concept is used when lifting heavy equipment or structural modules, and we have the team to do this for your project.

- Structural Building Modules

- Pipe Rack Modules

- Pipe Bridges

- Rooftop Equipment

Our long history and proven safety record permits us to operate in the strictest of build sites, including the Oil Sands. This opportunity is earned by only a few select teams.

PR Construction Ltd. can help you find the right heavy hauler for your project and we can work as a coordinated group to save you time and money.